With the advent of COVID-19, companies have struggled with getting back to work in a safe and healthy environment. As Delaware slowly recovers and businesses begin to re-open their doors, organizations need to ensure that their workplaces are CDC (Center for Disease Control) compliant. Without the proper protocols and protections in place, safety will be an issue. Planning for this eventuality, Senior Superintendent and Manager of EDiS Company’s Interiors/Service Division Joe Pedicone hatched an idea that was both simple and effective.

“Our customers were calling us, talking about how they wanted to come back and they wanted to do that as safely as possible. I started looking at what we could do besides full-sized office partitions, what can we do with reception desks, regular desks, meeting areas? I wanted to come up with an easy way to build and install something that would ensure our clients could be safe and compliant.”

“Our customers were calling us, talking about how they wanted to come back and they wanted to do that as safely as possible. I started looking at what we could do besides full-sized office partitions, what can we do with reception desks, regular desks, meeting areas? I wanted to come up with an easy way to build and install something that would ensure our clients could be safe and compliant.”

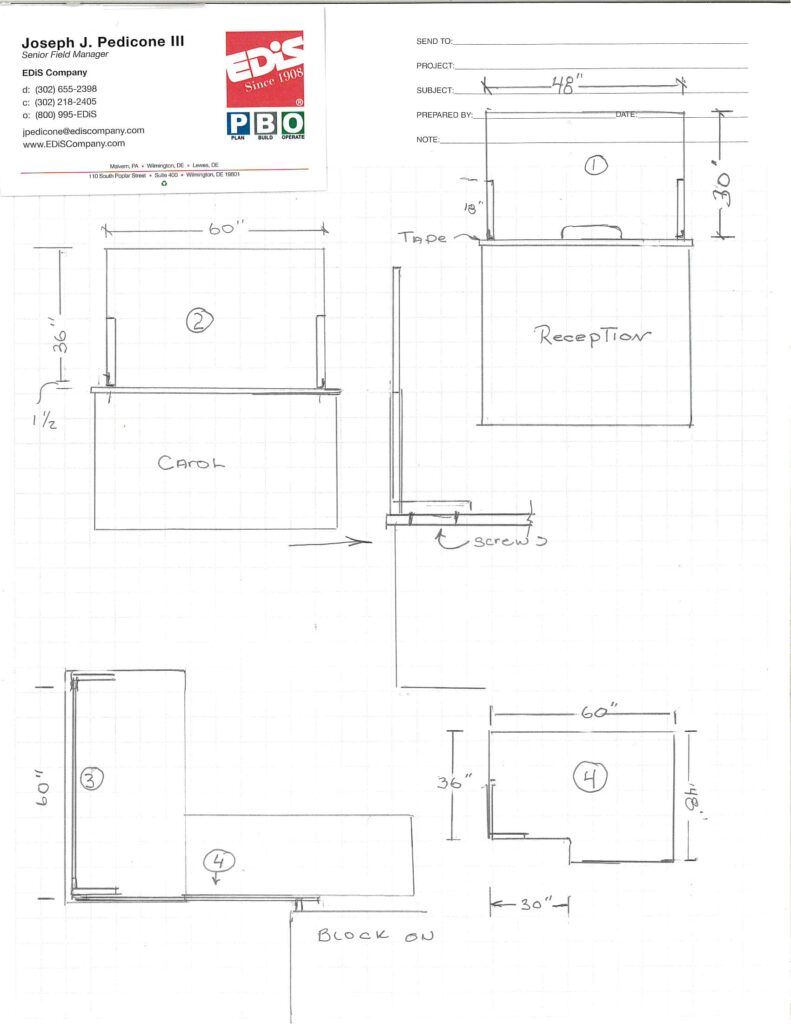

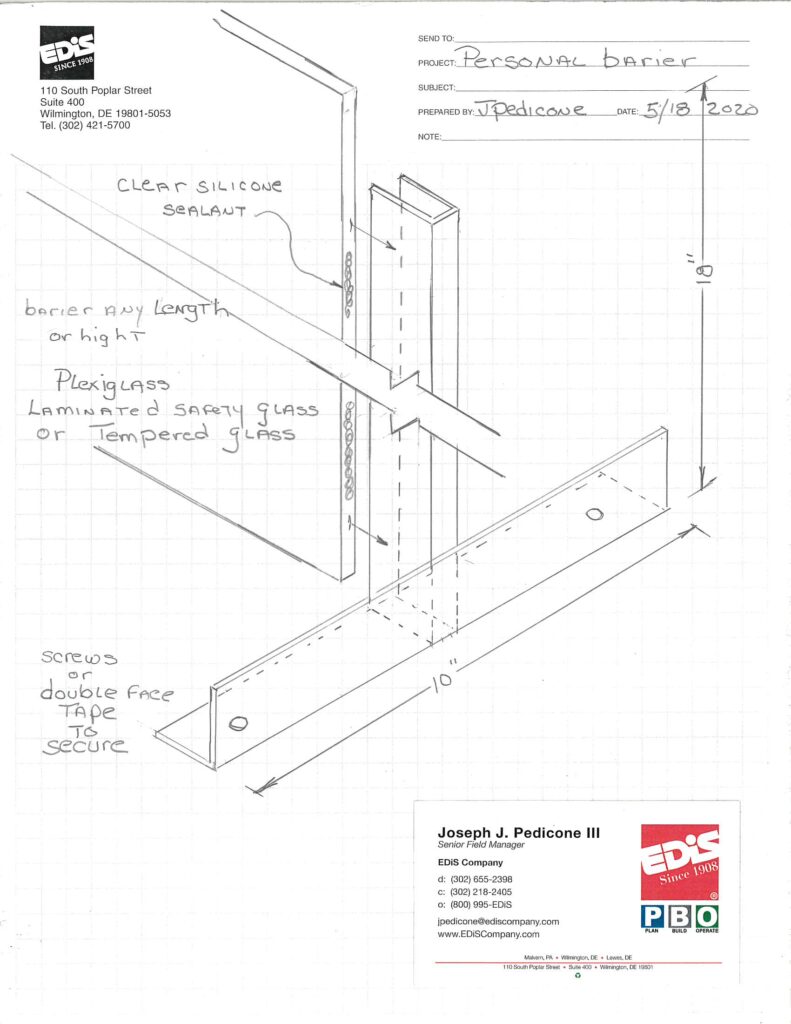

Joe’s solution was to manufacture and install personal barriers that organizations could utilize to conduct business while protecting those around them. He devised three different types of clear barriers: laminated, plexi, or tempered glass. Joe had a metal fabricator manufacture a 10×18 metal hinged barrier that could be installed on multiple surfaces using either screws or double-faced tape. The initial test build was ironically stalled by COVID-19, but now Joe can have them manufactured in as little as three days. The original barrier worked and was installed in EDiS Company’s office shortly after.

What makes Joe’s barrier design particularly affective is the ability to have them custom tailored to any space. The barriers can be different sizes and, depending on the installation area, different shapes. They also have the flexibility of being a full barrier or one with cutouts to pass materials through. Certain glass types can be cut to any required height or length and installation on most surfaces and materials is possible. The only question left for customers was how to install them safely without bringing in any outside contaminants. As usual, Joe had it figured out.

In order to protect against contaminants during installation, Joe brings a fogger machine to each site. This fogger machine is capable of pumping out the sterilization chemical Vital Oxide, which disinfects, sanitizes, and deodorizes all in one step. Not only do they run it while they enter for installation, but they use it upon exiting as well, ensuring a clean and sterile environment. The entire installation and cleaning process lasts only 30 minutes.

Joe made his stance on the matter very clear, reflecting a work ethic molded over 36 years, “We have to fulfill our client’s needs. We have to be at the forefront of safety, do the research, and make it safe for them to come back. These are bankers, restaurant owners, lawyers, blue and white collar both. They need to meet with people, and I’ll find a way to make that happen. Simple as that.”

Joe’s glass barrier designs outlined above.

Contact EDiS Company’s Joe Pedicone for more information:

jpedicone@ediscompany.com

Office Dial: (302) 655-2398